Acoustic tube burying technology

(1) D≤1500mm, three acoustic tubes are buried in an equilateral triangle arrangement; D>1500mm, four acoustic tubes are buried in a square arrangement.

(2) The metal tube is used, the inner diameter is 15mm larger than the outer diameter of the transducer, and the screw connection is adopted to prevent water leakage.

(3) Firmly welded or bound on the inside of the steel cage, parallel to each other, accurate positioning, buried to the bottom of the pile, and the nozzle is more than 300mm above the top of the pile. The bottom of the tube is closed and the mouth of the tube is capped.

(4) Take the vertex in the forward direction of the route as the starting point, number and group in clockwise direction.

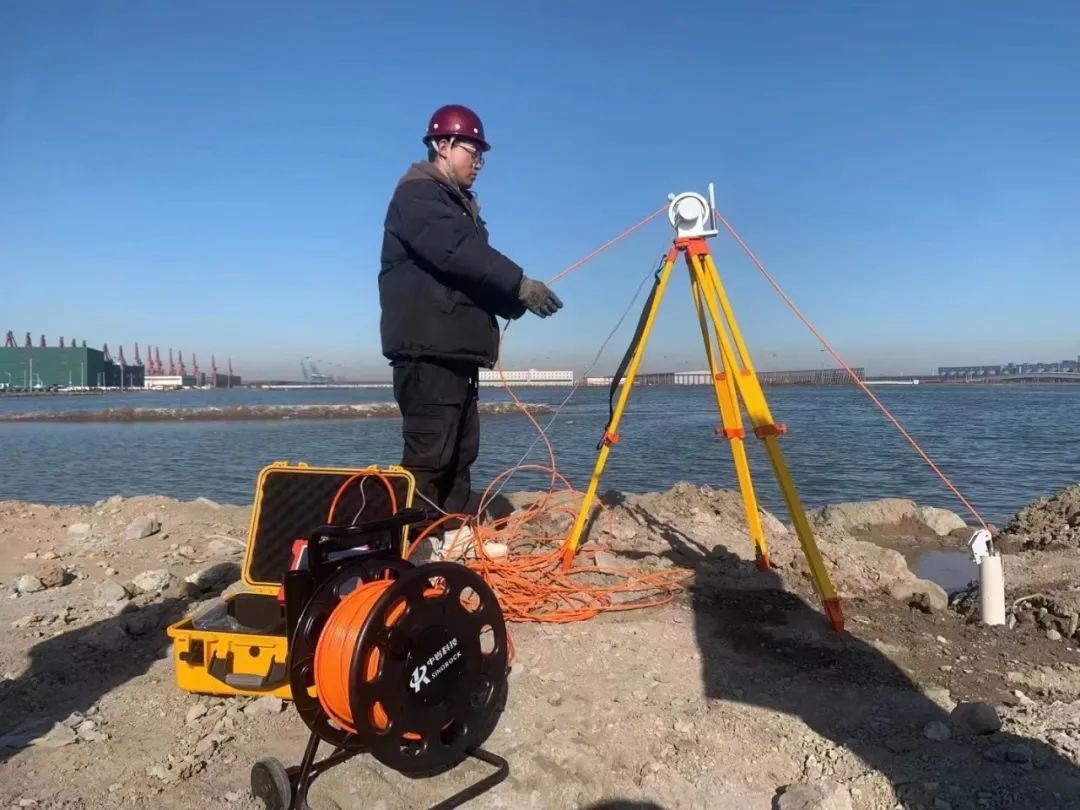

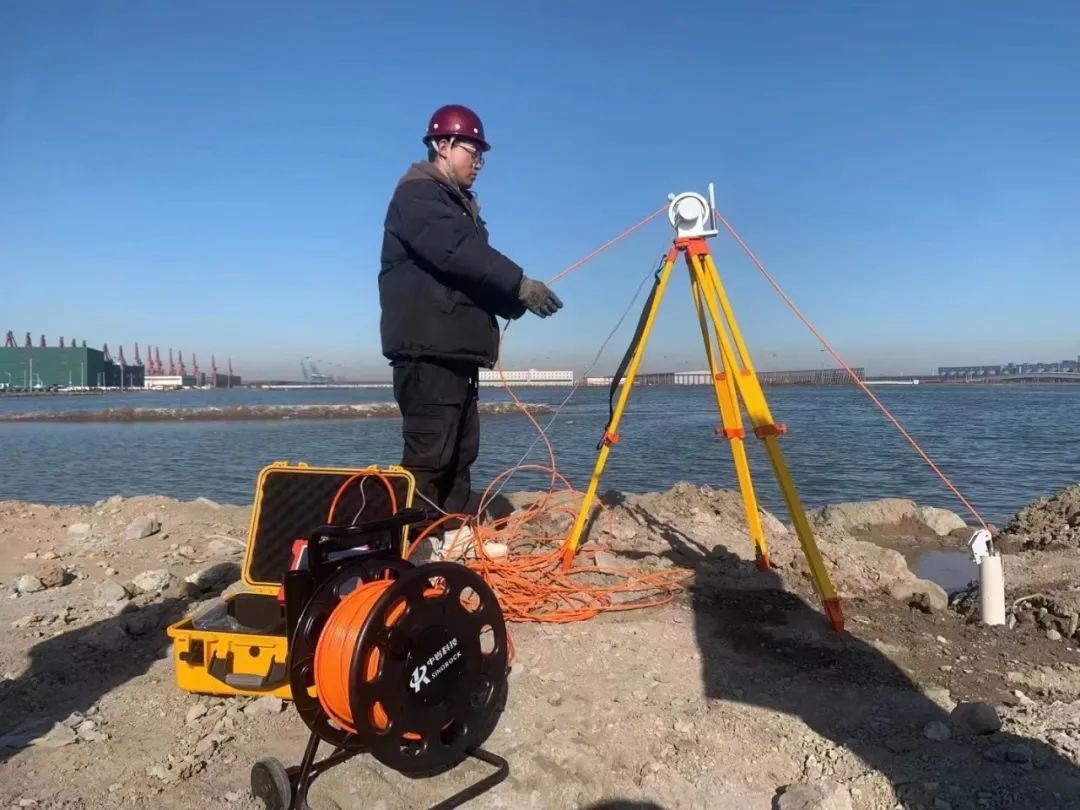

Acoustic tube burial and numbering indication

Preparations before testing

(1) Collect engineering geological data, pile design drawings and construction records, supervision logs, etc. to understand the construction technology and abnormal conditions during the construction process;

(2) Develop a testing plan;

(3) The age of concrete is more than 14d;

(4) The acoustic measuring tube is filled with clean water to ensure smooth flow;

(5) Calibrate the system delay time from transmitting to receiving of the acoustic wave instrument;

(6) Measure the inner diameter and outer diameter of the acoustic measuring tube, and the distance between the outer walls of adjacent acoustic measuring tubes, ±1mm

Taking the technical regulations for the detection of foundation piles in highway engineering as an example, the distance between the measuring points should not be greater than 250mm; the transmitter and receiver transducers rise and fall synchronously at the same elevation, and the cumulative error should not be greater than 10mm, which should be corrected at any time; during the detection of the same pile, the emission voltage remains unchanged change. For abnormal parts, use horizontal encryption, two-way oblique measurement or CT technology to carry out detailed measurement, and analyze the corresponding waveform diagram of the test to determine the severity of the foundation pile concrete and the location of the defect. When laying out the receiving and transmitting transducers, it should be ensured that the horizontal angle of the connection is not less than 30°.

Judgment of Integrity

1. Sound speed judgment basis The critical value of the sound speed is determined based on the probability method, that is, the sound speed measurement value of the pile foundation without defects, although it has a certain discreteness due to its own inhomogeneity, conforms to the normal distribution; the low sound speed abnormal value caused by the defect does not conform to the normal distribution. Therefore, when determining the critical value, the average and standard deviation of the sound speed of normal concrete must be used, otherwise the average value of the sound speed obtained will be too small, which will easily lead to missed judgments. At the same time, the influence of errors caused by the non-parallel between the acoustic tubes should also be considered.

The speed of sound is one of the basic physical quantities of materials, which is related to the strength of concrete. When the discreteness of the sound speed of the corresponding measuring points on the detection plane is small and generally low, the method of the lower limit of the sound speed can be used to judge it. The method for determining the lower limit value of sound speed is based on the results of the comparative test of the sound speed and compressive strength of concrete specimens with the same conditions, and then determined based on the actual experience in the region.

2. Basis for judging amplitude The magnitude of the critical value of the amplitude is the reduction of the average value of the amplitude by 6dB. When the actual measured amplitude is found to be less than the critical value of the amplitude, the detection section shall be regarded as a suspected defect area. The amplitude is obtained by relative test. Due to the great variability of the internal structure of the concrete of the pile body, it is difficult to find a better statistical regularity of the amplitude.

3. PSD judgment basis The judgment basis of the PSD method is that the slope of the sound wave depth curve will increase significantly when the sound wave passes through the defect, and the degree of the defect is closely related to the size of the acoustic time difference. PSD is often used as an auxiliary abnormality criterion. When it is found that the PSD value changes abnormally near a certain measurement point, it should be regarded as a suspicious defect area and further detected.

Precautions

When the sound velocity, amplitude and PSD value exceed the critical abnormality or sudden change, the defect should be carefully measured. At the same time, a comprehensive analysis is carried out in combination with relevant data such as waveforms, construction techniques and construction records to determine the location and extent of concrete defects in the pile body. When the speed of sound is generally lower than the lower limit, the concrete strength of the foundation pile should be tested by the drilling core method. Since ultrasonic waves can only detect the concrete quality of the pile body, for supporting piles or rock-socketed piles, the low-strain reflected wave method should be used to detect the supporting conditions of the pile ends at the same time to ensure that the bearing capacity of the foundation piles meets the design requirements.