With the widening of the application field of concrete pile foundation, pile integrity testing has become an important content of pile quality testing. If design is compared to the soul of construction products, then the construction quality, as one of the cores of construction project management, is the guarantee of the continuity of the soul and the key to determine the safety performance of buildings. Low strain reflection wave method and acoustic transmission method are the most commonly used pile integrity detection methods in field detection. The technology is mature and the effect is remarkable. So what are the similarities and differences between these two detection methods, and how should we choose them in the field detection?

Similarities between the two detection methods

From a macro point of view, both the acoustic transmission method and the low strain reflected wave method belong to the semi direct method, that is, they are based on the field prototype test, and at the same time, based on some theoretical assumptions and engineering practice and comprehensive analysis, they can finally determine the detection method of the results of the detection items. Both of them rely on the changes of some physical parameters to infer the integrity of the pile body. Like other physical detection methods, there are multiple solutions. For example, the defects such as cavity, mud inclusion, segregation and secondary pouring surface in the pile body cause changes in relevant parameters. Therefore, it is difficult to accurately indicate the defects only from the measured curve. Both of them must be comprehensively determined in combination with coring, excavation verification and on-site construction.

From the microscopic point of view, both the acoustic transmission method and the low strain reflected wave method are longitudinal waves, which study the mechanical waves caused by the particle movement, but the acoustic transmission method studies the vibration of the particle at the cross section of the pile body, while the low strain method studies the vibration of the particle at the contact point between the pile top and the sensor.

Both the acoustic transmission method and the low strain reflected wave method have the characteristics of portable equipment, simple operation, high detection efficiency, low cost and mature technology. Therefore, as a general survey method, they are widely used in engineering detection.

Differences between the two detection methods

1. Detection principle difference

The low strain reflected wave method regards the pile as a one-dimensional linear elastic rod, and the stress wave is reflected in the concrete "rod" where the pile impedance changes to form a reflected wave. Through the research and analysis of the reflected wave, the integrity of the pile can be determined.

The acoustic transmission method is to evaluate the quality of concrete and judge the integrity of pile body through the changes of some acoustic parameters after the acoustic wave penetrates the concrete. That is, the integrity of the pile body is mainly determined by the corresponding relationship between the acoustic parameters of the concrete and the concrete quality.

For example, if the quality of the test pile is compared to our experience in the hospital, the low strain reflected wave method is similar to the pulse diagnosis of traditional Chinese medicine, and the acoustic transmission method is more similar to a B-ultrasonic examination.

2. Wavelength difference

The stress wave length of the low strain reflected wave method is measured in meters, and the stress wave propagates along the longitudinal axis of the foundation pile. Therefore, the pile is required to be larger than the pile diameter for a long time, generally at least 10 times the pile diameter. At this time, the measured wave velocity is similar to that of the rod.

The wavelength magnitude of the acoustic transmission method is calculated in centimeters, and the transverse section of the pile is taken as the propagation direction of the wave. At this time, the measured wave velocity can be roughly regarded as the body wave velocity.

3. Difference in wave velocity

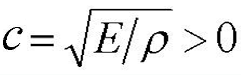

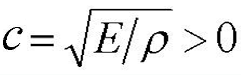

The wave velocity measured by the low strain reflected wave method is one-dimensional wave velocity. It is assumed that the ratio of pile diameter to pile length is small, and the wave velocity is related to the elastic modulus of the pile and the medium density.

Namely:

。

。

Where,E——Modulus of elasticity ρ——Medium density

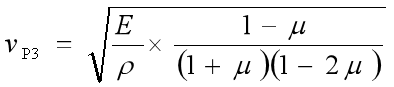

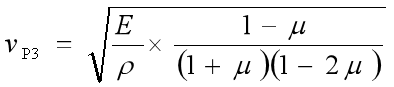

The wave velocity measured by acoustic transmission method is three-dimensional, and its sound velocity is related to the properties of solid media and the boundary conditions of solid media. Namely

:

:

Where , E——Modulus of elasticity μ——Poisson's ratio of mediumρ——Medium density

The Poisson's ratio of concrete is generally 0.2, so the wave velocity measured by low strain reflected wave method is generally less than that measured by acoustic transmission method.

4. Difference in detection range

The method selected may be different according to the length of the pile. The impact of factors such as the degree of percussion of low strain in the test process, the performance of the soil around the pile, and the coupling agent causes a certain energy loss in the transmission process of the wave. If the cross-section of the pile body changes greatly, it may be difficult to judge the subsequent pile body signal due to the influence of the reflected signal. If the length of the tested pile is too long, it may appear that the stress wave has not returned to the top of the pile or even reached the bottom of the pile, and the energy has been completely dissipated. When the signal received by the instrument is relatively weak, it will affect the integrity judgment of the pile body. Therefore, low strain detection will be limited by pile length and length diameter ratio.

The acoustic transmission method is generally not limited by the pile length. As long as the acoustic pipe can be set to the place, it can be effectively detected by the ultrasonic transmission method.

5. Sensitivity difference to pile defects

Due to its detection principle, the low strain reflected wave method can only judge the decrease and increase of wave impedance in the broad sense, and can not determine the specific defect type. It is not sensitive to the pile with gradual change of pile section. Especially for multi defect piles, the low strain reflected wave method can only determine the first serious defect from the top of the pile downward, and it is difficult to show the following defects.

However, the detection range of the acoustic transmission method only depends on the length of the acoustic pipe. No matter how many defects exist in the pile, the location and influence degree of defects can be accurately determined through the changes of acoustic parameters. If necessary, it can also be accurately measured by densified detection, oblique measurement, fan-shaped measurement and other methods, and even along the pile body per centimeter. The results are accurate and reliable, and there is relatively little human interference based on empirical judgment.

6. Detect differences in blind areas

Due to the influence of excitation mode, there is a detection blind area near the pile head in the low strain reflected wave method. The scope of this blind area is affected by the excitation frequency. The higher the excitation frequency, the smaller the shallow blind area, but at the same time, the deep blind area will be formed due to the rapid energy attenuation.

Due to its detection principle, the blind area of the acoustic transmission method is the concrete outside the acoustic pipe and the concrete area that cannot be tested by the detection profile. The diameter expansion and slight diameter reduction cannot be effectively detected. Whether for friction pile or rock socketed pile, the diameter expansion is conducive to improving the bearing capacity of the foundation pile. Therefore, in a practical sense, the blind area of the acoustic transmission method is the concrete area outside the acoustic pipe that cannot be tested by the slight diameter reduction range and the detection profile.

How to select during pile foundation testing?

Some experience

1. It is easy to test small defects of deep foundation piles by acoustic transmission method, but it is often impossible to test by low strain method.

2. The low strain reflected wave method is very sensitive to shallow defects, while the acoustic transmission method is difficult to detect defects outside the acoustic pipe and concrete areas where the detection profile cannot be tested.

3. If the pile is long and the pile diameter is large, the low strain reflected wave method is difficult to obtain the pile bottom reflection, so the low strain reflected wave method is not suitable for the detection of long piles with a length diameter ratio of more than 50. The acoustic transmission law is not limited by pile length and pile diameter.

4. Sound wave transmission method can not detect expanding diameter and slight reducing diameter.

5. When a few acoustic pipes are blocked or abnormal conditions occur in acoustic penetration detection, the design confirms whether the low strain reflected wave method can be used for detection, so as to better judge the integrity and grade of foundation piles.

6. For the foundation pile with large diameter and long pile body, 100% of the acoustic pipe shall be embedded, and the protective measures of the acoustic pipe shall be taken to prevent blockage or inclination. For the cast-in-place pile with small diameter and short pile body, some embedded acoustic pipes can be selected, and the low strain reflected wave method is mainly used for detection.

Conclusion

Through the above comparative analysis, we can see that both the low strain reflection method and the acoustic transmission method have advantages and disadvantages. A single detection method will have certain limitations in the process of pile detection, which can not fully reflect the actual situation of the tested pile. In important projects, it is suggested to use the low strain reflected wave method to assist the acoustic transmission method, and combine the construction technology and pile completion records to determine the integrity of the pile body, so as to improve the inspection quality, find problems in time, and reduce engineering hidden dangers.

。

。 :

: