Ultrasonic testing of piles for estimate abnormal phenomena and Analysis of the causes of defects

WEI Wei-ming,

(GuangXi Communications Planning Surveying and Designing Insti-tute,Nanning,Guangxi,530011)

Ultrasonic transmission method is used as a method to detect the quality of foundation piles, which can accurately find the defect position and defect range of foundation piles. According to the analysis of abnormal characteristics, the defects and the extent of defects are judged, and the integrity of the pile is evaluated according to the standards to provide guarantee for the stability and safety of the bridge foundation.

Principle of ultrasonic transmission method

Ultrasonic is a kind of elastic wave. The concrete medium is regarded as an elastic body. The propagation of ultrasonic waves in concrete obeys the law of elastic wave propagation.

Concrete ultrasonic testing mainly adopts the so-called "penetration method", which uses a transmitting transducer to transmit ultrasonic pulse waves to allow the ultrasonic waves to propagate in the concrete, and then the receiving transducers receive them. Concrete informations, the changes of these parameters can be accurately measured, and concrete properties, internal structure and composition can be inferred [1].

Concrete ultrasonic testing mainly adopts the so-called "penetration method", which uses a transmitting transducer to transmit ultrasonic pulse waves to allow the ultrasonic waves to propagate in the concrete, and then the receiving transducers receive them. Concrete informations, the changes of these parameters can be accurately measured, and concrete properties, internal structure and composition can be inferred [1].

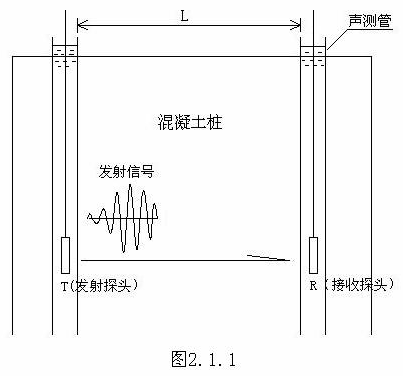

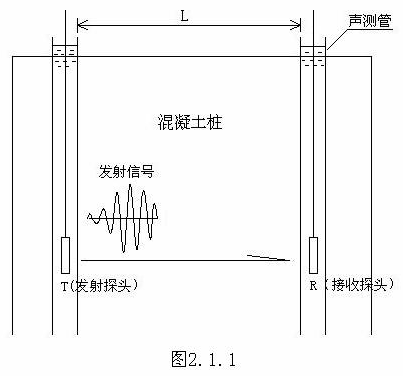

Ultrasonic testing of foundation piles is to embed the acoustic tube in the foundation pile, place the transmitting transducer and the receiver in the two acoustic tubes respectively, and fill the acoustic tube with water as the coupling medium (see Figure 2.1 .1). When the transmitting transducer emits ultrasonic waves, the ultrasonic waves propagate in the concrete and reach the receiving transducer and are measured and recorded. From this, the concrete sound velocity can be calculated:

(L is the propagation distance of ultrasound in concrete, T is the propagation time of ultrasound in concrete)

At the same time, the measurement of the received wave amplitude is to use a certain index to measure the height of the peak of the first received wave, and use them as a relative index to compare the strength of the acoustic signal at each measuring point in parallel [2]:

(A and A0 are the peak value of the first wave and the reference peak value respectively).

When there are defects such as honeycomb, segregation or mud inclusion in a certain section of the pile, the received ultrasonic signal will have the characteristics of reduced wave speed, reduced amplitude, waveform distortion, and change in the main frequency of the received signal. Ultrasonic transmission method of foundation pile detection is to analyze and judge the location and scope of defects based on the relative changes in the measured values of concrete acoustic parameters, and to evaluate the quality of pile foundation concrete [3].

Case

In Guangxi, the foundation piles of highways and bridges are all manually dug bored piles or bored bored piles. If there is a quality accident during the construction of the foundation piles, most of the phenomena such as concrete segregation, mud inclusion or honeycomb will occur, and segregation is the majority . In addition, although the abnormality caused by the deformation of the acoustic tube is not a problem of the quality of the foundation pile and concrete, it interferes with the judgment of the quality of the foundation pile, so this article also discusses it. In view of the above phenomenon, in the following discussion with typical examples for analysis.

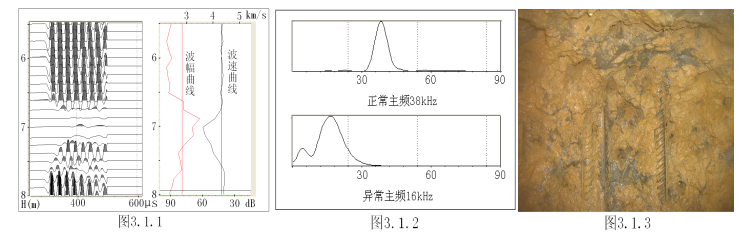

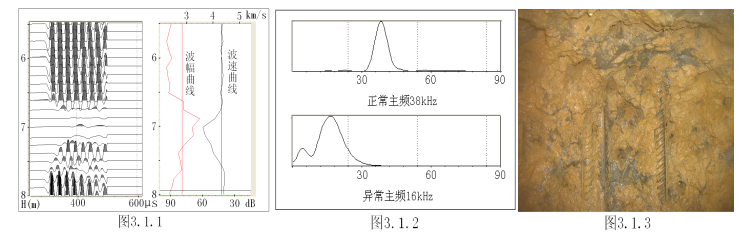

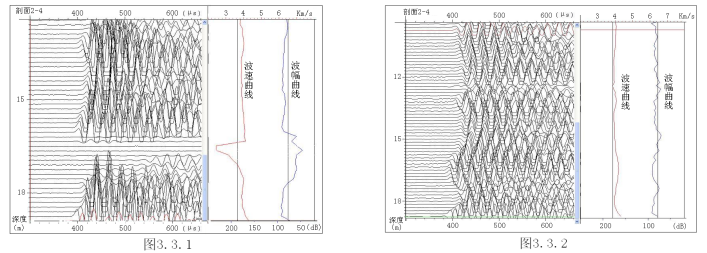

Concreting mud phenomenon in bored pile

The following picture shows the result of using RSM-SY5 ultrasonic logging instrument to detect a certain bridge foundation pile (see Figure 3.1.1). The normal waveform has a clear first wave, high amplitude, high wave speed, and regular curve, but obvious ultrasonic abnormalities appear at a depth of about 7m. , The first wave of abnormal waveform is difficult to identify, the amplitude of the weak wave is low, and the curve is severely distorted; from the spectrum analysis chart (Figure 3.1.2), the dominant frequency of the normal spectrum is about 38kHz, and the dominant frequency of the abnormal spectrum is about 16kHz. From the above analysis and combined with the construction technology, it is judged that there are serious defects such as mud or low-strength concrete, and it is judged to be a type III pile according to the pile integrity category [3]. Through excavation verification (see Figure 3.1.3), it was found that a large amount of mud inclusion did occur in the abnormal part.

The bridge is a bored pile, which is poured underwater with mud protection. Through analysis, it is believed that the reason for the above-mentioned defects is due to the blockage of the pumping concrete pipe and the continuity of the poured pile concrete is broken. The interval time is long and After the initial setting time is exceeded, the mud-in concrete begins to consolidate. When the concrete is subsequently poured, this part is buried in the pile to form a defect.

If the concrete watering stops during the construction process, if the time interval of breaking out exceeds the initial setting time of the concrete, the continuous watering should be stopped. According to the height of the poured concrete, it is decided to re-fill the hole or adopt the method of clearing the piles.

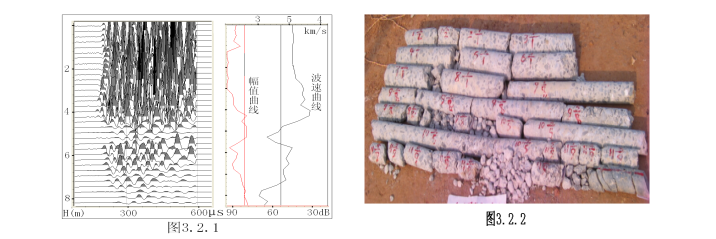

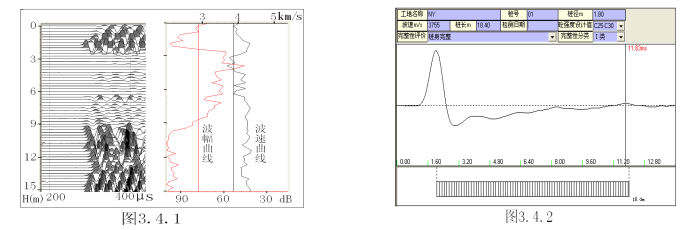

Phenomena of concrete segregation in manual digging piles

The following figure (Figure 3.2.1) is the result of using SY5 instrument to test a certain bridge foundation pile. At 5m and below 7.75m to the bottom of the pile, the ultrasonic wave amplitude is weak and the wave speed is extremely low. There is obvious abnormality in this section. Construction technology and abnormal characteristics, judge the separation of concrete at that place. Judging from the verification results of core drilling (see Figure 3.2.2), serious segregation of concrete occurred at the corresponding position of the ultrasonic abnormality. The coarse aggregate and the fine aggregate were separated or only a small amount of mortar was bonded, but the strength was low and no Form a hard consolidated body. Combining the results of ultrasonic method and core drilling method, the pile is judged to be a type IV pile.

According to the construction data, the pile is a manual digging pile, the bearing layer at the end of the pile is limestone, the karst is developed, and the groundwater is abundant. The analysis believes that due to the use of ordinary injection, a large amount of groundwater flows into it when the water is not drained or the concrete is poured. The gelling substance (cement) is washed away, so the gelling effect is lost and segregation is formed.

For this type of pile, when the groundwater gushing is too large to be drained in time and the level is high, underwater pouring is recommended. If the water level is low or the gushing volume is not large, you can try to mix dry cement with water to make it form cement slurry, to avoid segregation caused by flushing and diluting concrete.

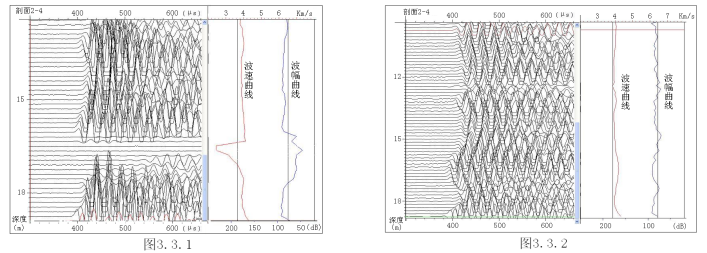

With the current level of foundation pile construction technology, the occurrence of voids and honeycombs is rare. Most of these situations are minor, and serious defects are extremely rare. In the foundation pile inspection of a certain bridge, it was found that a certain foundation pile had obvious abnormal phenomena. The height of the abnormal section of one of the sections was about 1m (see Figure 3.3.1), and the range of other sections was slightly narrower, and some sections had one point abnormal. Judging from the test results, the abnormal curve showed that the wave amplitude became weaker, the wave speed became lower, but the frequency did not decrease significantly, and there was no signal in some parts. Repeated observations were carried out in order to eliminate instrument factors, and the results still showed abnormal reflections.

After several times of heavy rainfall, re-testing was carried out. From the results, no abnormal phenomenon was found in each section (see Figure 3.3.2). After comparative analysis, it is believed that the above-mentioned honeycombs and small cavities are filled with groundwater, which causes ultrasonic can conduct normally in the pile concrete, so it shows normal acoustic information. Finally, it was determined that the pile had defects such as honeycombs and small holes in the above-mentioned parts, but the degree of defects was slight, and the pile was judged to be a type II pile.

In order to avoid the occurrence of such defects, wall protection and sealing should be done to prevent the occurrence of dry caves, regardless of size, during digging.

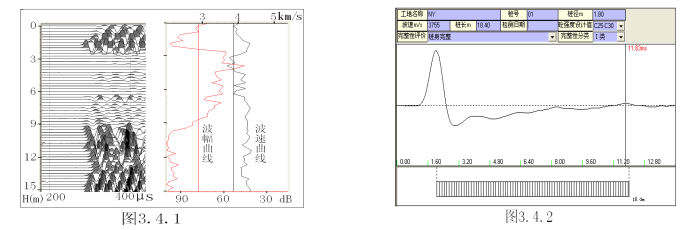

Acoustic tube problem

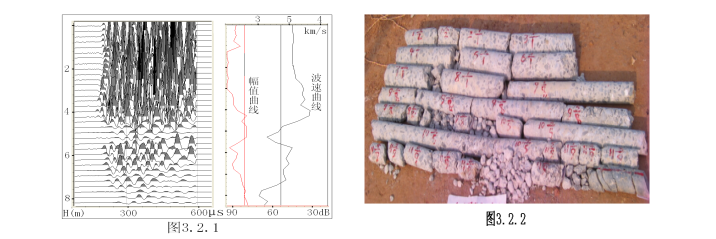

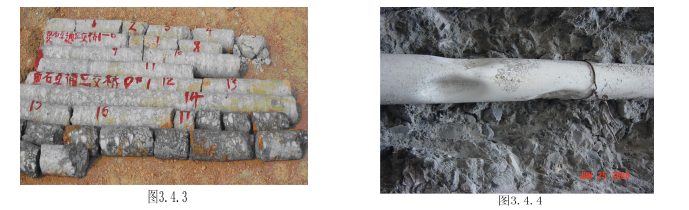

The figure below (Figure 3.4.1) is the result of using the SY5 instrument to test a certain bridge foundation pile. From the figure, only a weak ultrasonic signal is seen in the 2-9m section, its amplitude is extremely weak, and there is no obvious first wave take-off point. But the wave speed did not decrease significantly. Since all foundation piles of the bridge are above 9m (basically the same elevation) with the same ultrasonic anomaly characteristics, the low-strain reflected wave method was used for auxiliary inspection, and it was found that there was no obvious abnormal reflection in the piles. (See Figure 3.4.2), and there are discernible in-phase reflection waves at the bottom of the piles (the bearing layer is gravel mudstone). Based on this, it is judged that these piles have at least no major defects.

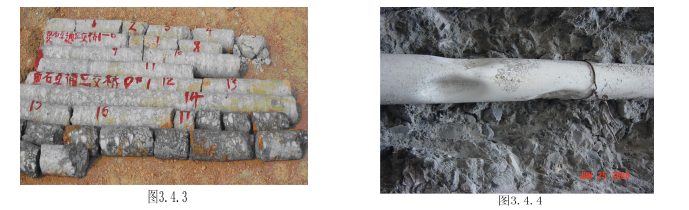

For the sake of prudence, two representative foundation piles were extracted for core drilling for further testing. The results (see Figure 3.4.3) found that the concrete core was complete and the concrete aggregate distribution was basically even, and no honeycomb, pockmarked surface and other phenomena were seen. In order to find out the cause of the abnormal ultrasonic wave, a foundation pile was selected for excavation verification. From the results of the excavation, no abnormality was found in the quality of the concrete pile, but the acoustic tube was severely deformed (see Figure 3.4.4).

The acoustic measuring tubes of the bridge foundation piles are all PV tubes. The reason for the deformation of the acoustic measuring tubes should be that after the concrete is poured, the hydration heat generated by the concrete during the condensation process has formed a high temperature, because the heat energy cannot be dissipated in time (located in the groundwater level) Above), causing the PV tube to soften and deform, so there is a gap between the PV tube and the concrete. Based on the above analysis, it is inferred that the above-mentioned ultrasonic abnormality is caused by the deformed acoustic measuring tube, combined with the ultrasonic method and the low-strain test results, it is finally determined that the quality of the bridge foundation pile is qualified.

In order to avoid this kind of phenomenon, it is required to use galvanized steel pipe when burying the acoustic tube.

Conclusion

Ultrasonic transmission method has obvious reflections on pile concrete segregation, mud and honeycomb defects, and can accurately determine the location and scope of the defects. According to the standard, the pile integrity evaluation can be carried out on the foundation pile. In order to verify the results of ultrasonic testing or when it is difficult to determine the completeness category (such as category II to III) during the ultrasonic testing process, further testing can be carried out with the help of high strain measurement method or core drilling method. Or conduct a static load test to comprehensively evaluate the foundation pile. Only by accurately evaluating the quality of foundation piles can the stability of the foundation and the safety of the bridge be guaranteed.

Concrete ultrasonic testing mainly adopts the so-called "penetration method", which uses a transmitting transducer to transmit ultrasonic pulse waves to allow the ultrasonic waves to propagate in the concrete, and then the receiving transducers receive them. Concrete informations, the changes of these parameters can be accurately measured, and concrete properties, internal structure and composition can be inferred [1].

Concrete ultrasonic testing mainly adopts the so-called "penetration method", which uses a transmitting transducer to transmit ultrasonic pulse waves to allow the ultrasonic waves to propagate in the concrete, and then the receiving transducers receive them. Concrete informations, the changes of these parameters can be accurately measured, and concrete properties, internal structure and composition can be inferred [1].