Comparison Examples

In 2015, Wuhan Sinorock Technology Co., Ltd launched several new types of high-tech intelligent testing equipment, among which the representatives are RSM-SY8 Ultrasonic Pile Integrity CT Imaging Tester and RSM-DCT (D) borehole television tester. Such equipment plays a significant role in improving the detection efficiency of testing organizations, accurately judging the positions, properties and range of defects in the pile body, and supplementing and verifying videos of drilling holes after coring. In recent engineering application, it has accumulated a number of engineering examples and data for comparison and verification of various testing methods.

Example One

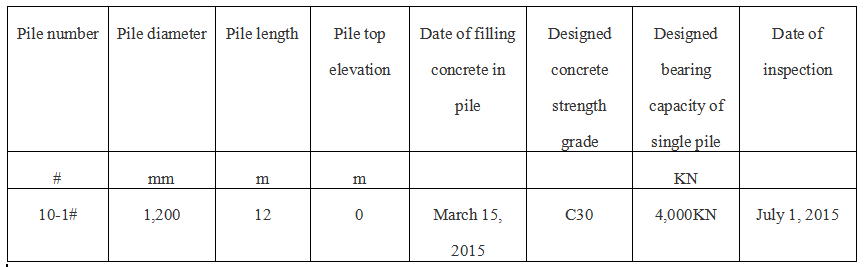

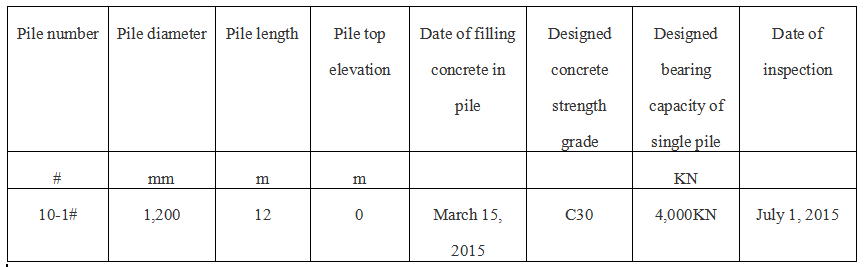

Based on the design and construction data provided by the client, the designed foundation pile diameter of this project is 1,200mm, designed pile length is 12m, and the designed concrete strength grade is C30.

This project is in Hubei. The type of testing pile is bored pile, whose length is 12 m and diameter is 1,200mm. The pile in the test was numbered 10-1#. The integrity of the pile was mainly tested.

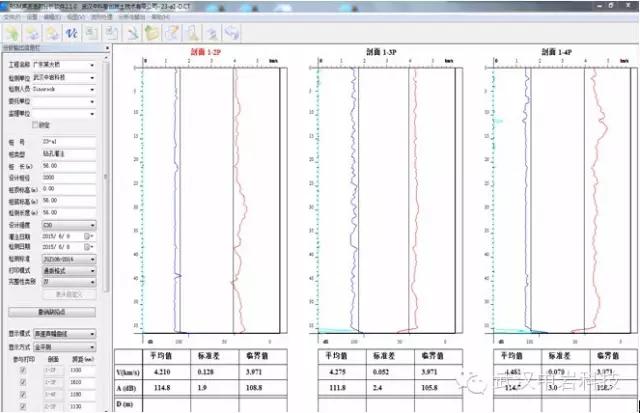

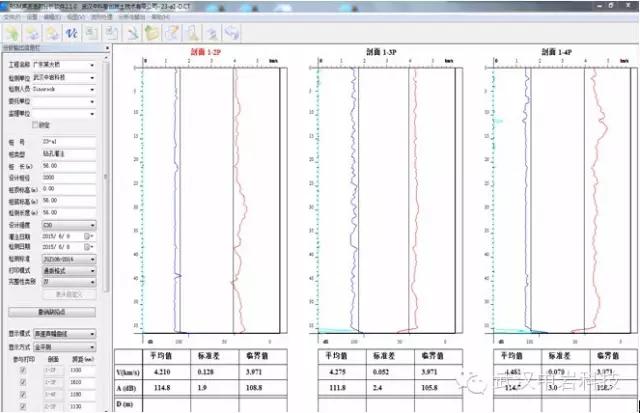

The integrity of pile body was detected through the ultrasonic transmission method with the RSM-SY7 pile foundation ultrasonic automatic measuring instrument of Wuhan Sinorock Technology Co., Ltd on site. The results are as follows:

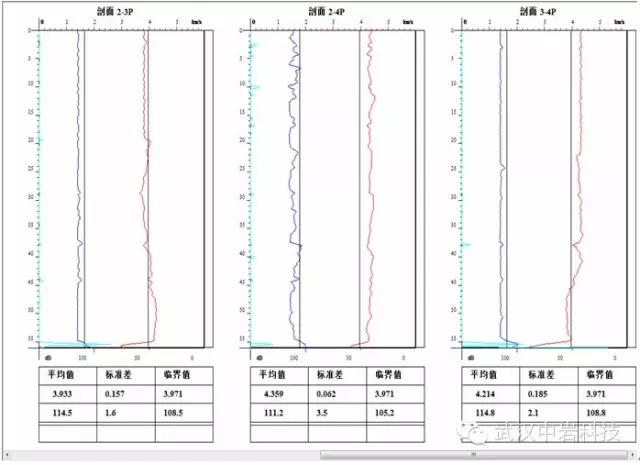

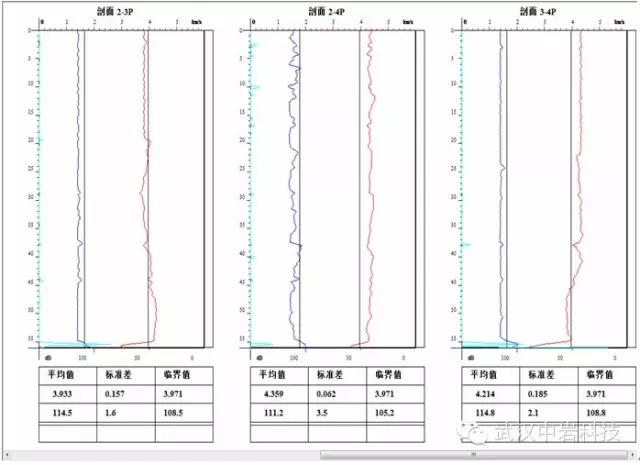

According to the testing results of ultrasonic transmission method, two positions of the pile were found to have defects. In order to more clearly locate the defects, the RSM-SY8 foundation pile ultrasonic CT imaging tester of Wuhan Sinorock Technology Co., Ltd was used. The details are as follows:

Based on the above CT imaging results, defects were found at the heights of 4m-5.5m and 8.2m-8.4m respectively from the top of the pile. And the defects at the height of around 5m from the top of the pile were especially serious.

The method of core drilling was used to further confirm the integrity so as to verify again the defects of the pile.

The position of curve in the pile could be judged basically through core drilling method. There were obvious defects at the height of 4-5m and minor defects at the height of 8m from the top of the pile. In order to locate the defects more clearly, the method of borehole television camera was used to further detect the bore holes.

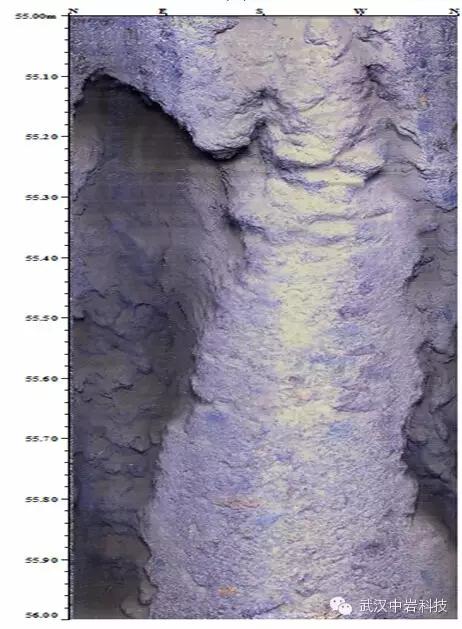

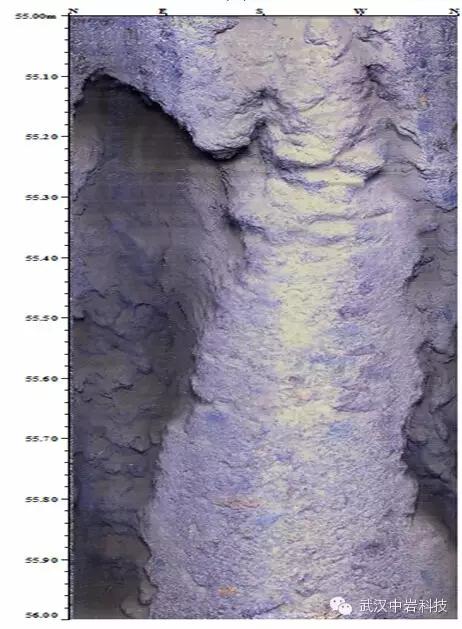

RSM-DCT(D) Borehole TV Tester produced by Wuhan Sinorock Technology Co., Ltd was used in this project to detect images of boreholes after coring.

RSM-DCT (D) Borehole TV Tester was used to inspect the core drilling hole of the pile and observe the testing pictures through camera. Serious crack could be seen clearly at the height of 4m-5m and slight cracks could be seen at the height of 8m from the top of pile. The following conclusion can be reached: There were serious defects at the height of 4m-5m, and slight defects at the height of 8m from the top of the pile.

Example Two

Based on the design and construction data provided by the client, the designed foundation pile diameter of this project is 2,200mm, designed pile length is about 74m, and the designed concrete strength grade is C30.

This project involves a bridge in Fujian. The type of testing pile is bored pile, whose length is 74 m and diameter is 2,200mm. The pile in the test is numbered 15-2#. The integrity of the pile body was mainly tested.

According to the specification, the integrity of the pile should be detected. The acoustic pipe was preburied before the pile is formed. The integrity of pile body was detected through the ultrasonic transmission method. The results are as follows:

Two defects were found in the pile by using the ultrasonic transmission method.

In order to more clearly locate the defects, the RSM-SY8 Ultrasonic Pile Integrity CT Imaging Tester of Wuhan Sinorock Technology Co., Ltd was used. The details are as follows:

Based on the above CT imaging results, apparent defects were found at the height of 2.8m-3.2m and 5.4m-6.5m respectively from the top of the pile.

The method of core drilling is used to further confirm the integrity so as to verify again the detects of the pile.

Based on the Ultrasonic Pile Integrity CT Imaging Tester CT 3D imaging effect, the position (between No.3 pipe and No. 4 pipe) which has serious defects are detected through core drilling method.

After core driling, the construction contractor complained that the ultrasonic testing results are inconsistent with the coring photos, and thus doubted the ultrasonic testing results. As the coring person was provided by the construction contractor, in order to further identify the type of defect and verify the site condition, the core hole was detected with the Drilling TV Imager.

RSM-DCT(D) Borehole TV Tester produced by Wuhan Sinorock Technology Co., Ltd was used in this project to detect images of boreholes after coring.

RSM-DCT (D) Borehole TV Tester was used to inspect the core drilling holes 3-4 of the pile and observe the testing pictures through camera. Mud could be seen clearly at the height of 5.4m-6.5m from the top of pile. The following conclusion can be reached: There was mud partially at the height of 5.4m-6.5m from the top of the pile.

Example Three

This project involves a bridge in Guangdong. The type of testing pile is bored pile, whose length is 56 m and diameter is 2,000mm. The pile in the test is numbered A9-4#. The integrity of the pile body was mainly tested.

According to the specification, the integrity of the pile should be detected. The acoustic pipe was preburied before the pile is formed. The integrity of pile body was detected through the ultrasonic transmission method. RSM-SY7 Four channels Cross Hole Sonic Logging Tester was used to detect the integrity of the pile through ultrasonic transmission method, and serious defects were found at the bottom of the pile .

To accurately figure out the defect range, RSM-SY8 Ultrasonic Pile Integrity CT Imaging Tester was used to detect the integrity of the pile body. 3D imaging was conducted on piles and the severity and position of defects were quantitatively analyzed.

By 3D imaging, the severity of defects at the bottom of the pile could clearly be seen in wave velocity chromatography. The position of pile bottom became more conspicuous when oblique grid was added.

From the 3D histogram generated automatically by CT software, the position and size of the defects can be clearly seen. According to the specification of “JGJ106-2014”, the pile is directly classified as IV pile.

The pile was cored for verification at the requests of the client. However, due to the limitation of coring technique, the cores at the bottom of the pile are incomplete, with only half of the defective parts covered by CT imaging. The defects can not be exactly identified. The result of the detection was doubted.

To further identify the defects, RSM-DCT (D) Borehole TV Tester was used for image quality test of the core hole after drilling core.

The defect range is consistent with the imaging data of 3D imaging effect of RSM-SY8 Ultrasonic Pile Integrity CT Imaging Tester after identifying the pile image by the RSM-DCT (D) Borehole TV Tester, and the depths of defects are the same. The defects are obvious, and the nature of defects is defined as large hollow.

From the above examples, it can be seen that, during practical engineering, conventional double-channel or multi-channel ultrasonic tester can judge the defects of foundation pile. For example, in conjunction with RSM-SY8 Ultrasonic Pile Integrity CT Imaging Tester, all parts of the pile can be imaged in 2D and 3D mode, which plays a crucial role in the judgement of the position and range of defects and provides an important basis for testing organizations to determine the severitiy of the defect of the whole pile. Traditional core drilling method is very subjective and has many limitations. RSM-DCT (D) Borehole TV Tester, however, can be used to take photos of the inside of the holes to further verify the pile quality, defects and bearing layer. Compared with traditional core drilling method, it ensures authenticity of cores, causes no damage to cores and reflects more accurate and reliable results.