Self-developed technology

Deformation measurement is a necessary part of infrastructure projects, which can timely provide monitoring and early warning for the construction safety and operation safety of engineering projects. Photogrammetry has become a new research direction of engineering deformation measurement because of its advantages of non-contact, high precision, multi-point real-time, convenience and rapidity. The research on Photogrammetry Technology in foreign countries has been carried out early and has formed a commercial model. Due to late start and technical blockade, domestic research work in this direction is still in the stage of laboratory exploration and research, and there is less application research in the field of large-scale infrastructure engineering.

The 13th five-year plan for national scientific and technological innovation attaches great importance to the substitution of disruptive technologies for traditional industries, and proposes to build an independent and controllable technology system, promote the industry to move towards high-end development, and grasp the international competitiveness and initiative. In order to improve the independent innovation and R & D capability of key fields and major intelligent complete sets of equipment, the national key R & D plan "development of major scientific instruments and equipment" came into being.

In 2018, the project was officially launched. In view of the great significance of the project, high technical difficulty and tight scientific research cycle, Sinorock technology has established a scientific research team with rich R & D experience and combat effectiveness. The average age of the team is 35. It is such a young and energetic team that, faces the difficulties, takes the lead in the research of long-distance, large field of view and non-contact three-dimensional video deflectometer, and resolutely wins the battle of key core technologies.

After more than three years of research and development, the team has broken through the key technologies such as 3D image acquisition, high-resolution analysis of low-quality images, self calibration of large field of view cameras, fast image matching and 3D fast positioning algorithm, laser absolute ranging modulation signal frequency reduction and phase discrimination method, and achieved the overall technical goals of long-distance, large field of view and high-precision 3D deformation measurement of multi-point targets and safety evaluation and analysis. The first large field of view three-dimensional deflection non-contact measuring instrument in China has been developed, forming a series of large facility deflection non-contact measuring instruments with completely independent intellectual property rights, making China's large field of view three-dimensional deflection non-contact measuring high-end equipment fully autonomous and controllable. China's three-dimensional deformation non-contact measuring technology has reached the international advanced level, and promoted the leapfrog development of engineering testing technology.

A total of 27 team members won 189 achievements, including 23 intellectual property rights of the national major scientific instrument and equipment special Non-contact Bridge Static and Dynamic Deflection Tester. Once the project achievements are promoted, they will quickly obtain government support, industry license, value recognition and form industrialization.

Assist the smart city, protect the project quality

The detection system realizes multi-point dynamic and static three-dimensional deflection real-time non-contact measurement and safety assessment analysis of large facilities, significantly improves the efficiency and accuracy of structural safety assessment of existing or under construction large facilities, not only reduces the labor cost and intensity, but also provides more accurate measurement data, effectively improves the technical level of prevention and control of major structural safety accidents, and improves the level of public safety, Reduce economic losses and adverse social impacts, and have broad application prospects. At present, the project achievements have been successfully applied to major projects such as Wuhan Yangtze River tunnel, Nanjing Yangtze River tunnel, yingwuzhou Yangtze River Bridge, Qingchuan Bridge, Wuhan Second Yangtze River Bridge, yangsigang Yangtze River Bridge, hoisting machinery, power transmission towers, etc., ensuring the safe operation of the facilities. The application unit Wuhan Yangtze River Tunnel Co., Ltd. evaluated that "this achievement has provided suggestions for the construction impact and construction scheme of the proximity project; it has evaluated the safety of the tunnel civil structure, provided suggestions for improving the quality, efficiency and maintenance of the tunnel, and produced huge social benefits". The application unit China Railway Bridge Research Institute Co., Ltd. commented that "the application of this achievement in the fatigue damage detection and fatigue life prediction of the suspenders of Qingchuan Bridge has provided useful support for the decision-making of the bridge management and maintenance department, and achieved remarkable social benefits".

Xinhuanet China Science and Technology News Network

Xinhuanet China Science and Technology News Network

Learning power China.com - Science China

Learning power China.com - Science China

Wuhan Construction Industry 2022 issue 4 (total 189)

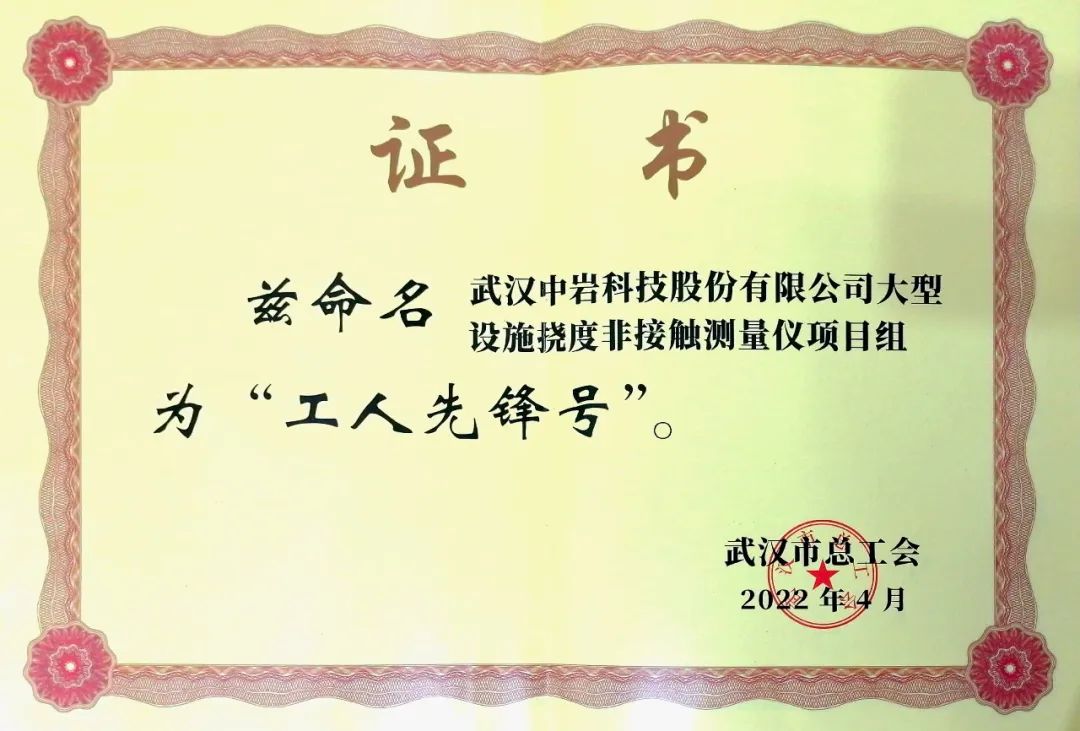

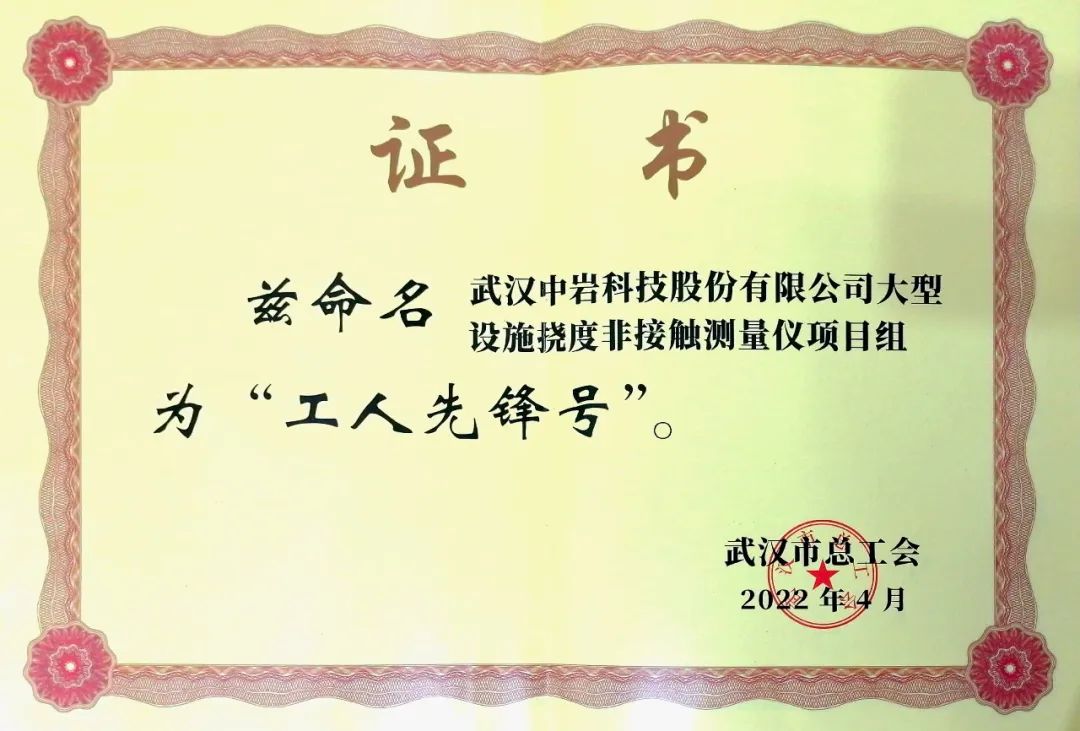

Wuhan Construction Industry 2022 issue 4 (total 189) Worker pioneer’ awarded by Wuhan Federation of trade unions to the project team

Worker pioneer’ awarded by Wuhan Federation of trade unions to the project team

An improved non-contact measurement method of bridge deflection based on monocular vision

Development of monocular video deflectometer based on inclination sensors

Remote deflection measurement using monocular video system

Inertial measurement unit aided extrinsic parameters calibration for stereo vision systems

2. Nine patents

A deflection measurement system and method based on stereo vision ZL201910892014.1

An intelligent logistics system and method based on binocular vision 202010387791.3(under review)

A parameter calibration system and method for long distance large field camera

202010494104.8(under review)

Monocular deflection meterZL202030753400.6

Deflection measurement method of monocular camera based on elevation change of target point

ZL201910469356.2

Binocular stereo vision measurement method and system based on IMU calibration

ZL201910575918.1

A calibration method and system for external parameters of bistatic camera

202010504026.5(under review)

Method, device and deformation simulation device for determining detection accuracy based on physical simulation 202111119183.5(under review)

A deflection measuring device based on stereo vision for lifting machinery

202011137567.5(under review)

3. Two software

Sinorock technology RSM-FBN non-conact bridges static and dynamic deflection tester analysis software V1.0

2021SR1305575

Sinorock RSM-FBN non-conact bridges static and dynamic deflection monitor system V1.0

2021SR1297388

4. Six standards

Technical standard for construction of geotechnical engineering deformation and safety monitoring database system

Technical specification for monitoring and measurement of soft rock tunnel

Technical specification for inspection of engineering structures by digital image method

RSM-FBN (A) non-contact bridges static and dynamic deflection tester

Technical specification for safety monitoring of urban bridge and tunnel structures

Non-contact deflection detection method of hoisting machinery based on digital image processing technology

5. Three awards

Top ten innovations award of the innovation group of the third ‘Gongyou Cup‘ employee innovation and entrepreneurship competition in Wuhan

The 25th National Invention Exhibition RSM-FBN (A) won the gold award of innovation and entrepreneurship Award project award

The project team of non-contact deflection measuring instrument for large facilities was awarded worker pioneer by Wuhan Federation of trade unions

The application scenario of infrastructure construction industry is only the first direction for the promotion of project achievements. In the future, it will be expanded and applied in industrial manufacturing, aerospace, wind power, rock coal mining, ancient cultural heritage and other fields, giving full play to the technical advantages of high-precision large-scale deformation measurement and safety assessment of the project, so as to create greater economic benefits and social value.

Under the background of promoting the development of professional equipment in the direction of high-end and intelligence in China, and with the support of the key special project of the national key R & D plan "development of major scientific instruments and equipment", the research team of Wuhan Sinorock Technology Co., Ltd. took the lead in carrying out the Research on long-distance, large field of view and non-contact three-dimensional video deflectometer, and launched a series of commercial large-scale facility deflection non-contact measuring instruments, The monopoly of foreign countries on high-end instruments and equipment for non-contact three-dimensional optical measurement has been broken. The key core technologies have reached the international advanced level, and some technical indicators have reached the international leading level.