Pile dynamic testing is a complex theoretical and practical system, which involves many disciplines, and requires careful operation in actual engineering to ensure the accuracy of various data, otherwise it will produce unpredictable consequences. Different from the low strain test, the high strain test requires two absolute quantities to be measured, namely the force F and the velocity V. The accuracy of these two quantities will affect the reliability of the bearing capacity of the pile. Special attention should be paid to the following issues in the high strain detection process:

1.Application limitations

From the theoretical derivation process of the CASE method, it is not difficult to see that due to the harsh assumptions, first of all, assume that the pile is uniform, which is generally easier to meet for precast piles, but for cast-in-place piles, most situations are more difficult to meet the premise; Furthermore, it is assumed that the dynamic resistance generated by the relative movement of the pile and soil is completely concentrated on the tip of the pile, and the actual situation is that when the pile is driven, with the relative displacement of the pile and soil, the pile side will inevitably generate dynamic resistance.It’s just relatively small. Finally, assume that the static resistance model is a rigid-plastic body, that is, once the pile is moved, the static resistance will immediately reach the limit value. This assumption is also somewhat inconsistent with reality. Therefore, to measure piles with CASE method, the full static resistance of the soil must be fully exerted on the premise that the pile is moved, the reflection position of the pile tip must be correctly judged from the waveform and the appropriate damping coefficient Jc value can be selected to determine the unit accurately. The ultimate bearing capacity of piles, and the selection of Jc value is not only related to the type of pile tip soil, but also related to the impedance of the pile, which determines that the CASE method is mainly applied to the test of precast piles. Under certain conditions, it should be actually controlled , And the selection of the experience coefficient should ensure that the final error is within the allowable range.

2.Preparation of the test site

(1) It is necessary to understand the pile type, pile outer diameter and geometric dimensions, concrete strength grade, construction method, geological condition, bearing method, building grade, etc., and clarify the inspection requirements based on these.

(2) For the concrete cast-in-place pile, the buoyant layer of the pile head must be chiseled off to expose the dense layer without loosening. The top surface of the pile head should be level and flat, and the central axis of the pile head and the central axis of the pile body should coincide. The main reinforcement of the pile head shall all pass directly under the concrete protective layer of the pile top, and the main reinforcement shall be at the same height.

(3) Reinforce the pile top 1 times the pile diameter, and strictly implement pile dynamic regulations.

3.The sensitivity of the sensor

The accuracy of a high-quality test curve is mainly determined by the sensor. If the sensitivity of the sensor is not enough or the calibration is not accurate, it will have a bad influence on the test result. Strain gauges and accelerometers used in pile dynamic tests should be calibrated regularly.

4.Installation of the sensor

1. The sensors must be installed symmetrically. On both sides of the pile body that should not be less than 2 times the pile diameter or the pile circumference from the pile top, the test signals can be averaged to eliminate the impact of hammering off-center. Never install the sensor on one side.

2. The installation of the sensor must have a dedicated person responsible for it, and it cannot be installed by temporary workers. In particular, the location of the strain gauge must have a good plane and be close to the pile wall. Use expansion screws to fasten the pile body to the dense concrete of the pile body. It cannot be bent, loose or poorly contacted. If the strain is not tightened, the waveform will vibrate naturally. The waveform signal does not return to zero, causing the signal to be unreal. So make sure that the sensor and the pile body deform together.

3. The center of the strain sensor and the acceleration sensor should be on the same horizontal line, and the horizontal distance between the strain sensor and the acceleration sensor on the same side should not be greater than 100mm. The central axis of the sensor should be parallel to the central axis of the pile, and the mounting surface of each sensor must be flat and vertical, and it should be ground to prevent the sensor from being installed at an angle, which may cause untrue collected data.

5.The choice of hammering force

The pile dynamic (CASE method) test is to apply force to the pile to excite all the static friction resistance of the pile to determine the bearing capacity of the pile. Therefore, the magnitude of the hammering force and its pulse width are the key to the high-strain test. If the force is too small, the condition of driving the pile required by the CASE method cannot be achieved, and the measured bearing capacity will be lower. If the striking force is too large, the relative displacement of the pile-soil will greatly exceed the displacement required for the frictional resistance to be fully exerted, and the resulting static resistance is actually caused by damping, and the result will be too large. Under normal circumstances, based on practical experience, the weight of the hammer should be selected not less than that required by the regulations, and the drop distance should be roughly estimated based on the ratio of about 40% of the total energy of the falling hammer to the pile to ensure that the maximum striking force reaches the maximum. Well, of course, for different site types, different pile types, accurate control of force still requires a lot of practice.

Furthermore, it is the pulse width of the excitation force. In theory, it should be a narrow pulse force. The narrower the better, the resolution can be improved, and the delay of static resistance to dynamic resistance can be reduced, and the analysis accuracy can be improved. Therefore, it is necessary to ensure that the hammer is a free fall or hammer during the test.

6.Hammer weight and drop height

For high-strain dynamic test piles, in order to produce a certain relative displacement between the pile and the soil, a large amount of energy is required to act on the pile. Therefore, the top of the pile must be hammered with a heavy hammer. The hammer type is preferably an integral hammer type. Testing and verifying that the overall hammer type is better than the combined hammer type. The hammer weight required by the regulations is generally 1% of the ultimate bearing capacity of a single pile. The drop height is an important factor affecting the peak pile top speed. Generally, the drop height is between 0.8m-2.0m and cannot exceed 2.5m. The low impact of the heavy hammer is the basic principle to ensure the accuracy of the pile dynamic method to detect the bearing capacity.

The advantages of "heavy hammer and low hammer height":

(1) The low impact of the heavy hammer can avoid the stress concentration caused by the "high impact of the light hammer", and the stress concentration is likely to cause plasticity or even damage to the pile material;

(2) The pulse action time of the low impact load of the heavy hammer is long, and the load changes slowly, which can cause the pile to produce larger settlement displacement;

(3) The low impact of the heavy hammer, the smaller the speed of the pile, and the smaller the rate of speed change, so the influence of dynamic resistance is small, which can reduce the influence of dynamic damping parameter errors on the fitting analysis and improve the accuracy of the fitting analysis;

(4) The low-strike action of the heavy hammer can be similar to the rapid loading in static load and the static and dynamic method test.

7.The influence of concrete strength on test data

If you want to obtain real results and collect reliable data to make the force and speed curves ideal, you should strictly follow the regulations to achieve the design strength level for the concrete cast-in-place pile before high-strain testing can be performed. If the concrete strength does not reach the design strength test, the result is only for reference. Through years of testing and a large number of tests, it has been proved that in the high strain testing, it is very suitable for the precast pile type, and the difference between the tested bearing capacity data and the static load is very small. However, the contrast between the bearing capacity and the static load of the concrete piles is very large. This can only show that the specified conditions should be met when high-strain concrete piles are tested. Because it is restricted by many conditions, among them, it is not detectable if the design strength level is not reached. Even if it is tested, the bearing capacity value will be low.

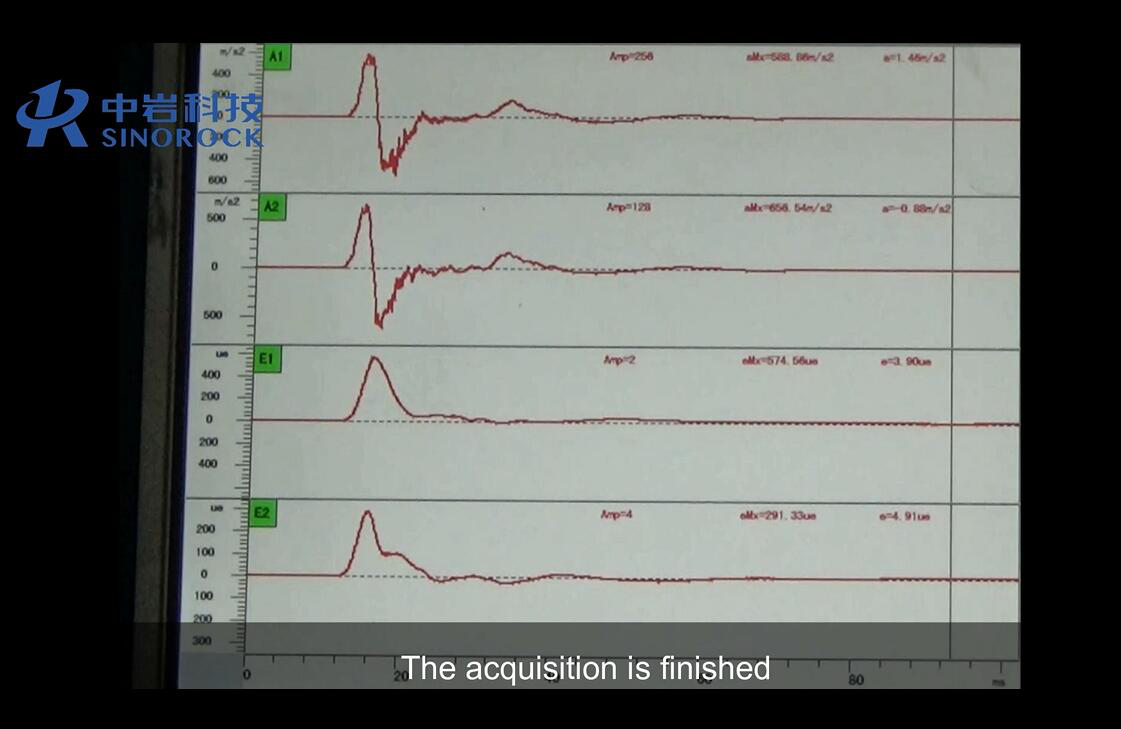

8.Data collection and processing

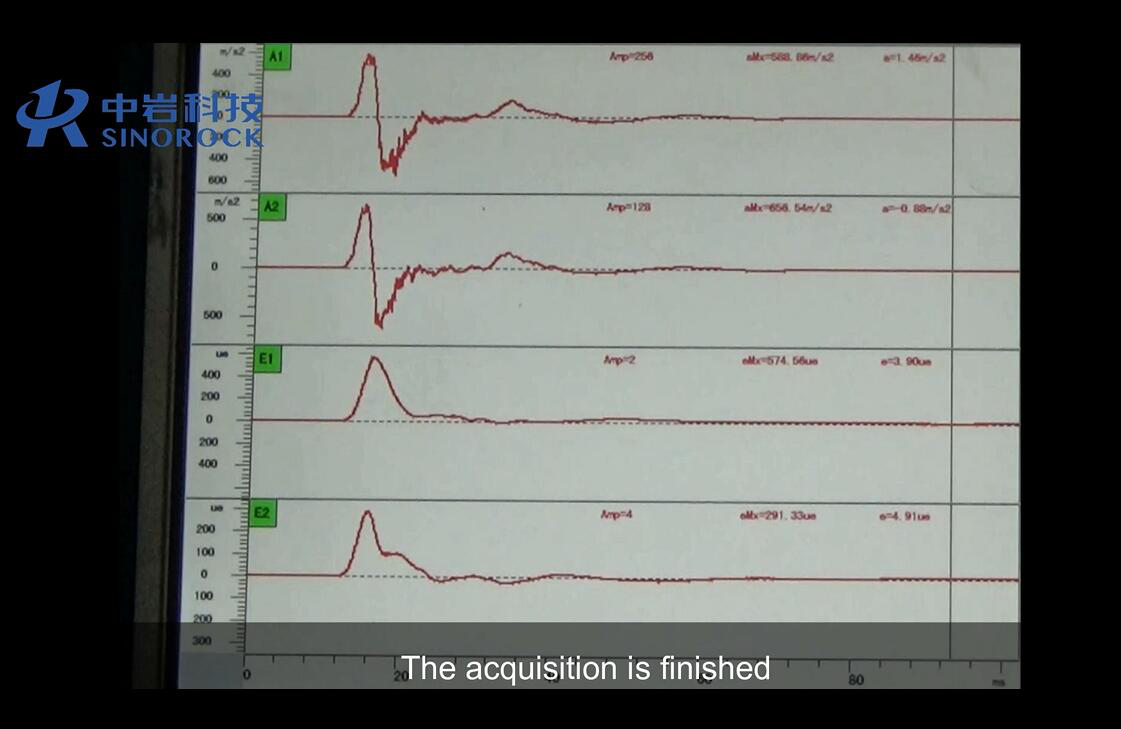

Data collection and processing is the final link of high-strain testing. Because high-strain testing is a field work, accurate control and discrimination of signals also need to be performed on site, so that it can be adjusted in time to eliminate unfavorable factors. Two points should be paid attention to in data acquisition: one is the signal magnification. Since high strain is a high-energy excitation, the magnification of the strain gauge and speedometer should not be too high to avoid clipping; the other is the acquisition interval Meets the test characteristics of high strain. It requires the collection of the entire vibration waveform from the beginning of the pile to vibrate until it hardly moves. This requires the recording time to be long enough and the sampling interval to be relatively large. However, too large sampling interval will lead to low bearing capacity or misjudgment of defect locations. In order to better solve this contradiction, the parameters should be selected reasonably according to the pile forming conditions on the spot, which also requires the inspectors to constantly explore and sum up experience in practice.

High-quality on-site measured signals generally have the following characteristics:

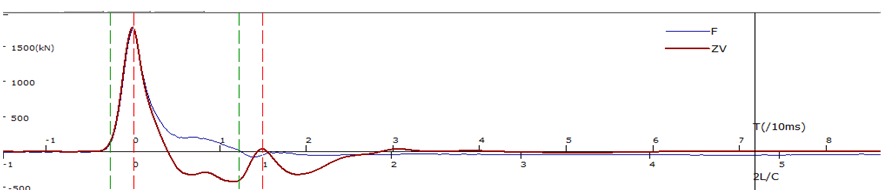

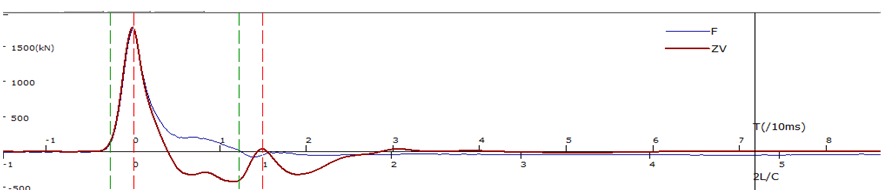

(1) The two sets of force and speed process curves are basically the same.

(2) F and ZV curves generally coincide at the peak. (Except when there are defects in the shallow part of the pile or when the shallow soil layer has high resistance)

(3) F~t curve and ZV~t curve will eventually return to zero. The D~t curve converges on the time axis.

(4) With sufficient sampling length, the fitting method requires the fitting time length to be max{4~5L/c, 2L/c+20ms}.

(5) The waveform has no obvious high-frequency interference, and there is obvious pile bottom reflection on the friction pile.

(6) The penetration should be 2~6mm. The penetration is too small and the soil resistance is insufficient. If the penetration is too large, the movement of the pile is obviously rigid. The wave characteristics are not obvious, and the wave theory is quite different from the real motion state of the pile, which is not applicable.

The processing of the signal is mainly the interpretation of the signal on the spot and the processing in the room, and the former is the key. If the ideal curve cannot be collected on site, then indoor processing will not be discussed. The on-site discrimination of collected signals requires not only a solid theoretical foundation, but also a lot of practice. Not only do you know what a collected signal is, but also Knowing why, so we can better complete the test.

The above are the main problems that are often encountered in the detection of high-strain engineering. Pile foundation engineering is a concealed engineering. The judgment and analysis of the integrity and bearing capacity of the pile body should integrate various factors. Provide a reasonable basis for pile foundation design and construction acceptance. For a test project, the requirements of each unit involved are different. The construction party wants the progress and quality, the supervision party wants the process, the designer wants the result, and the inspection party has the dual responsibilities of a doctor and a judge. How to request our test party, we should follow the rules and regulations, so as to draw the most accurate conclusions.